- Available ISO Ratings: ISO 5, ISO 6, ISO 7, ISO 8

- +1 (714) 578-6100

Mon - Fri, 5:30 AM - 5:30 PM, PST

Terra Universal offers custom fabrication to provide the optimal solution for your application.

Examples of requested modifications include:

Watch Terra's Smart Pass-Through Video

Watch Terra's Smart Pass-Through Video Smart® Pass-Through Chambers by Terra Universal

Smart® Pass-Through Chambers by Terra Universal Stainless Steel Air Showers: Standard and Custom Designs

Stainless Steel Air Showers: Standard and Custom Designs Cleanroom Air Shower

Cleanroom Air Shower

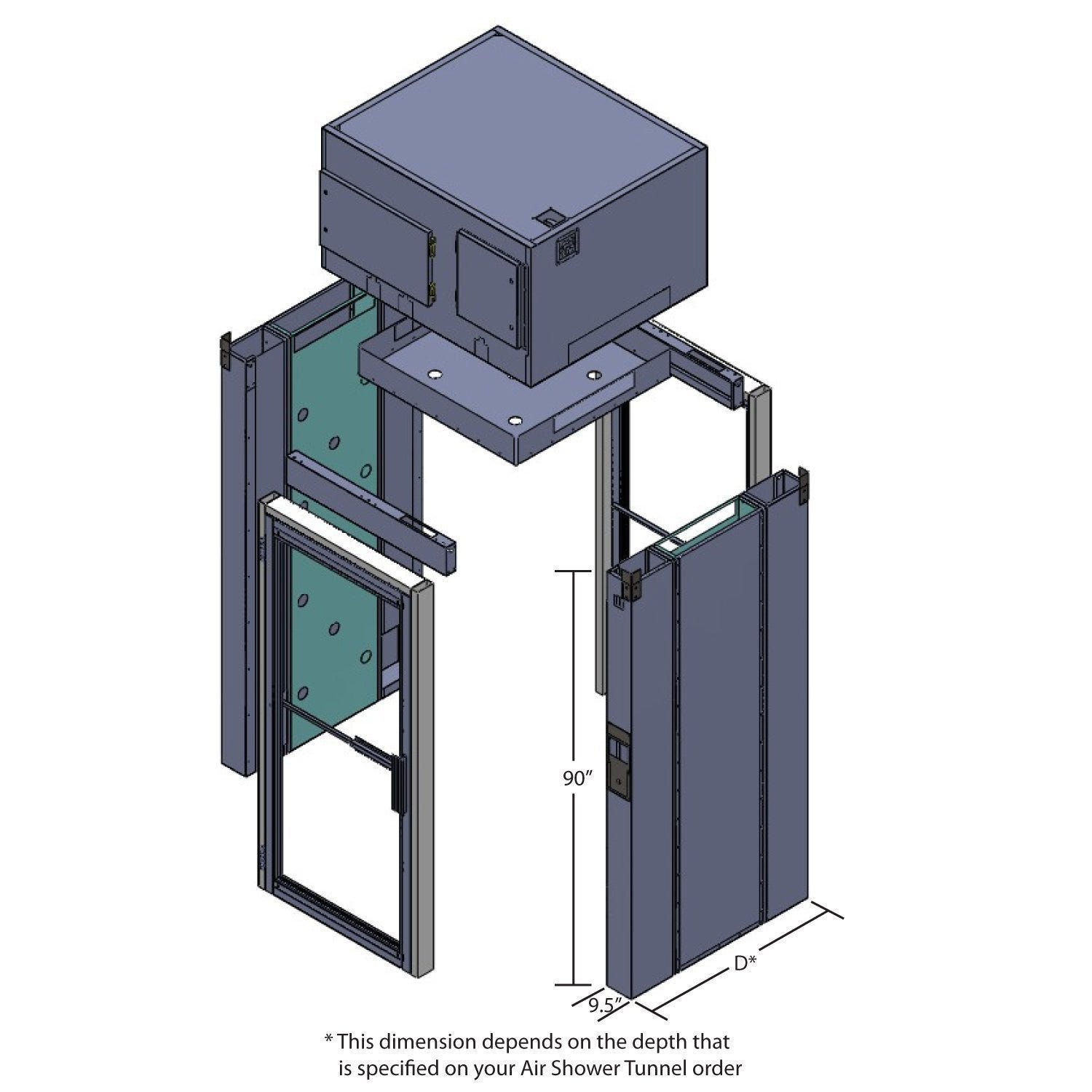

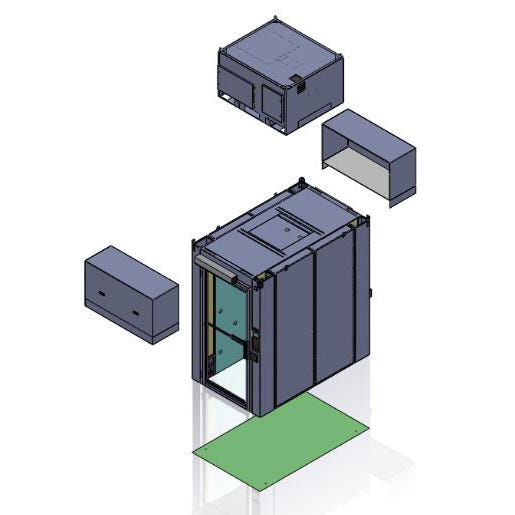

An air shower is a self-contained enclosure that uses high velocity jets of HEPA filtered air to help decontaminate personnel and equipment prior to entering or exiting a controlled environment. The inside of the airshower is lined with multiple evenly distributed nozzles, pointed at various angles to optimize the air scrubbing process. The nozzles shoot concentrated streams of class 100 micro-filtered air to shake off and wash away loose particles and other contaminants clinging to the surface of personnel or equipment.

Operating as a closed-loop system, the particle-laden air is vacuumed out through exit vents along the bottom of the air shower. The air passes through pre-filters to capture larger particles before being pushed by the fan blower through HEPA or ULPA filters to capture remaining smaller particle contaminants. The pressurized filtered air then recirculates through the nozzles to continue the cleaning process.

Read more about air shower designs and applications.

Decontamination air showers are used across many industries in facilities with different policies and cleanliness requirements. The most common industries include semiconductor, pharmaceutical, biological, industrial, and food/beverage.

In most cases, air showers are used to protect sensitive products/procedures inside a controlled environment, such as a cleanroom, from microscopic contaminants carried in by personnel. For cleanroom or lab applications, most facilities place an air shower at the entrance to a gowning room to reduce contaminants carried or generated by street clothes, prior to garbing with cleanroom apparel. These contaminants include fine particles such as dust that can ruin sensitive electronics, and also biological contaminants such as infectious fungus spores that can ruin sensitive plant crops or other cell cultures. Other facilities position air showers between the gowning area and the cleanroom, for workers to enter after they complete the garbing process. Cleanroom air showers and tunnels are also used to decontaminate equipment and other bulky materials (such as carts or loaded pallets) prior to entering a cleanroom.

For manufacturing facilities or construction areas with excessive hazardous metallic or organic dusts (for example lead, silica, asbestos, or wood dust), decontamination air showers can be used at exits to remove the microscopic particles from personnel or equipment. This helps contain the dangerous dusts produced in the manufacturing area and protect people outside manufacturing from harmful exposure that can cause serious if not fatal diseases.

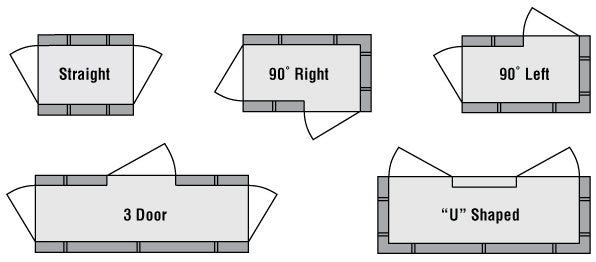

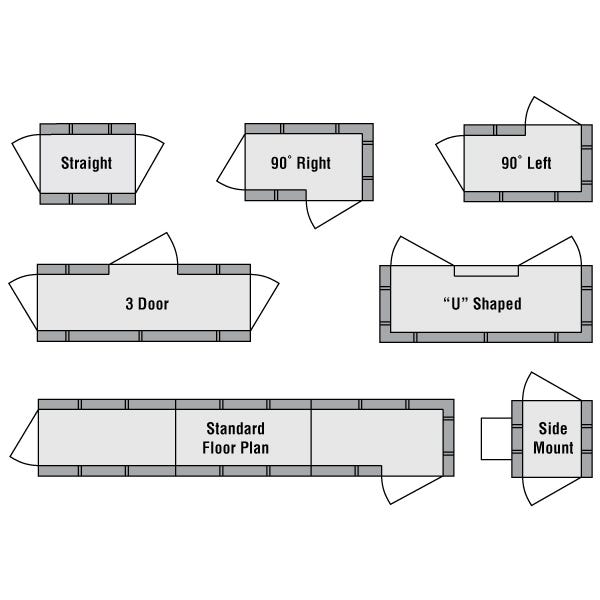

Terra offers standard cleanroom air shower and tunnel configurations plus countless customizable options for any application. The most popular and economical air shower design is the standard 2 door straight configuration, with the blower module mounted on-top of the enclosure.

Below is a list of common configurations and options. Call or chat with a product specialist to find the optimal solution for your unique requirements:

Terra Universal offers UL-listed and ETL-listed air showers for third party safety certification.These listings help meet municipal and other permitting requirements that may apply while ensuring the safety and integrity of high voltage electrical components.

Both are certified by OSHA as nationally recognized testing labs (NRTL) that test to nationally accepted safety standards. ETL can offer a quicker turnaround time for highly custom projects with short timelines. The NRTL status tells all customers that the testing services performed by these third party companies are reliable and legally binding throughout the United States. ETL,originally known as Edison Testing Laboratories, is an old, respected, nationwide testing group with credibility equal to UL or CSA.

Terra offers two shipping options:

All of Terra’s air showers feature a fully customizable and easy-to-use touch-screen PLC. This microprocessor control comes programmed with the ability to:

The control panel can be easily programmed for other unique requirements such as custom interlocking sequences and connection to building management systems (BMS).

The frequency at which the air shower HEPA filter needs to be replaced varies depending on several factors such as total operation time, quality of ambient air (dirty or humid ambient air will shorten the life of the filter), and maintenance of air shower prefilters.

Under average conditions, Terra recommends replacing HEPA filters every 2-3 years to avoid unexpected maintenance delays. Below are a few methods to determine when to replace the HEPA filter. It is important to note air showers use one HEPA filter per blower. Thus larger air shower systems may have multiple HEPA filters (one for each blower).

The control panel includes the ability to measure filter back pressure and alarm for filter replacement when the backpressure reaches the user defined setpoint. The control panel also includes a “run times” feature where personnel can keep track of how much air shower operation time and cycles have elapsed to help in setting up a filter replacement maintenance protocol.Lastly, it is recommended to periodically monitor the air velocity at the nozzles with an air velocity meter. The air velocity will initially average up to about 8,000 FPM, measured at each air nozzle. When the readings drop to below 80% of the initial value, the corresponding HEPA filter is approaching the end of its useful service life and is recommended to be replaced.

When the shower cycle commences, pressurized air streams from adjustable nozzles at a velocity of up to 8,000 feet per minute (41 meters per second). This ensures the necessary efficient scrubbing action to remove particulate matter.

You can rate the efficacy of the air shower by measuring the air flow velocity at each nozzle. Each nozzle is designed to provide up to 8,000 feet per minute of air flow. If the measured velocities fall significantly short of 8,000 feet per minute, check whether the HEPA filters need to be replaced.

On a tight schedule? Choose FasTrak 24/7 Priority Service to help meet your critical schedule for Terra-manufactured products, either before or after your order is placed.*

Call for pricing. FasTrak service fees cover costs of additional services only, without additional profit.

* Terra's FasTrak services limited guarantee: to ship on the ESD or date specified OR to refund up to 100% of FasTrak charges. This guarantee covers no direct, special, consequential or other damages and is strictly limited to up to 100% of the amount paid for FasTrak service. When a specified ship date is missed due to factors outside Terra's control (vendor performance, deliveries by shipping companies, etc.) and random factors such as accidents, the credit of up to 100% of the FasTrak 24/7 may not apply. FasTrak service requested after order placement will be quoted and accepted based on available time remaining before required ship date.