Can't find what you're looking for?Tell us what you need and we'll build it!

- +1 (714) 578-6100

Mon - Fri, 5:30 AM - 5:30 PM, PST

Laboratory hoods serve a number of critical purposes in the lab environment.

Such hoods, often called laminar flow workstations or clean benches, use a flow of HEPA-filtered air to prevent influx of viable and non-viable particles into the enclosure and to sweep away any contaminants generated by the work process.

For fume containment, laboratory fume hoods use a ducted ventilation system that maintains negative pressure. Where ducting is impractical, ductless hoods are also available for removal of non-hazardous contaminants (fumes or particles), using either HEPA or activated carbon filters.

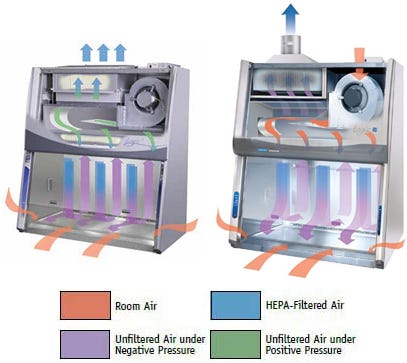

Biological safety cabinets combine aspects of both hood types: a laminar flow of micro-filtered air and negative-pressure containment of bio-hazard fumes.

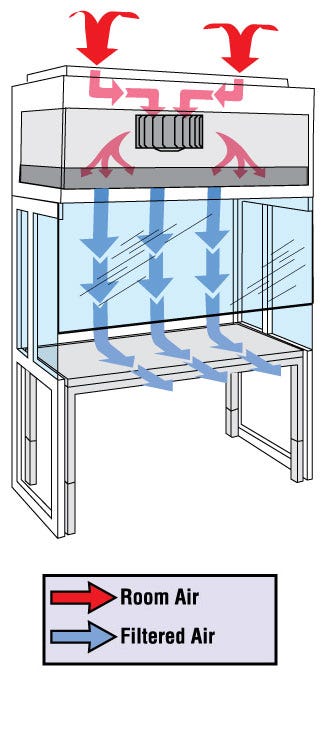

Laminar flow hoods (also called laminar flow clean benches) force air through a HEPA or ULPA filter to create a clean work area free of nearly all contaminating particulates, including bacteria, mold spores and many viruses. These hoods use a vertical or horizontal airflow design. Both provide excellent protection of products from particulates and cross-contamination, but do not protect the operator or environment.

So why choose one over the other? Vertical laminar flow hoods (VLF Hoods) require less floor space, but more overhead clearance. In addition, a sash at the front of the VLF hood provides a barrier between air exiting the hood and the operator’s face. VLF hoods create turbulent air flow when air strikes the work surface, requiring sterile work to be performed above the work surface.

HLF hoods minimize air turbulence (and particle backflow) on the work surface except where equipment disrupts the horizontal airflow. However, they direct the airflow directly at the operator’s face and require more depth to accommodate placement of the fan filter unit at the rear of the hood.

Read more about the differences between horizontal and vertical laminar flow hoods

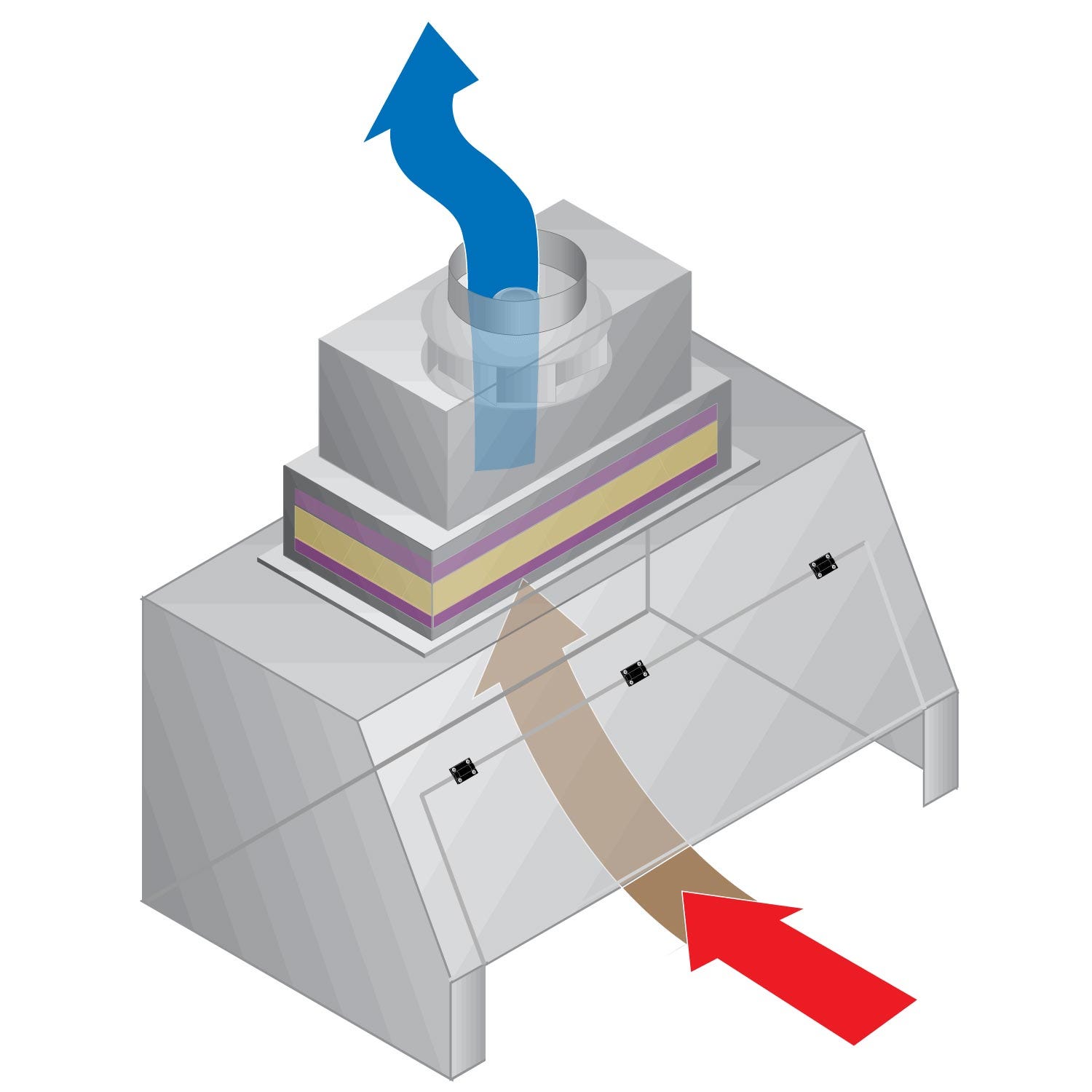

Laboratory fume hoods draw air from the environment through the opening of the hood, allowing environmental contaminants into the work area. Thus, lab fume hoods do not offer a sterile environment or product protection. Instead, chemical fume hoods are designed to protect the operator from dangerous or irritating fumes and powders generated from work performed inside the hood.

In ducted fume hoods and canopy fume hoods, air passes out of the hood through a duct leading to an in-house ventilation system that contains and/or neutralizes hazardous materials.

In ductless fume hoods, fans draw exhaust air through a series of filters that remove irritating substances before release back into the room. Since these filters are not 100% efficient in removing all substances, ductless fume hoods are not advised in the presence of biohazards; however, they provide a convenient, cost-effective solution for operations involving irritating but non-hazardous fumes in facilities where an in-house HVAC system cannot be accessed.

Biological Safety cabinets combine design aspects of both laminar flow and fume hoods. Filtered air is directed downward onto the work surface and then travels into a plenum through openings on the front and sides of the hood. Depending on the classification of the biosafety hood, some percentage of air is recirculated through a HEPA filter while the rest is directed out of the hood through an exhaust system. Thus, biosafety cabinets offer operator, environmental and product protection.

These laboratory safety cabinets (sometimes called IV hoods or compounding hoods) are ideal when preparing sterile medications such as chemotherapeutic agents that may pose a risk to the operator.

When it comes to working with hazardous or potentially infectious material, protecting personnel must be the primary concern. However, offering personnel protection does not have to come at the cost of risking product integrity. Class II BSCs provide protection to both personnel and product simultaneously. They maintain an ISO class 5 clean work area for product manipulation, while ensuring that exhaust air is filtered and ducted out of the environment. Thus, a class II BSC is the ideal solution when working with moderately hazardous material and both personnel and product safety are required.

Read more about these lab hoods here regarding their biological safety rating

HEPA Filtration for Particle-Free Airflow

HEPA Filtration for Particle-Free Airflow Isolated Work Surface Enhances High Magnification Viewing

Isolated Work Surface Enhances High Magnification Viewing ValuLine™ Vertical Laminar Flow Stations

ValuLine™ Vertical Laminar Flow Stations PLC Touchscreen Panel on Vertical Laminar Flow Hood

PLC Touchscreen Panel on Vertical Laminar Flow Hood Tilt-Up Shield

Tilt-Up ShieldCan't find what you're looking for?Tell us what you need and we'll build it!